- February 12, 2026

- Predictive Maintenance, Professional Services

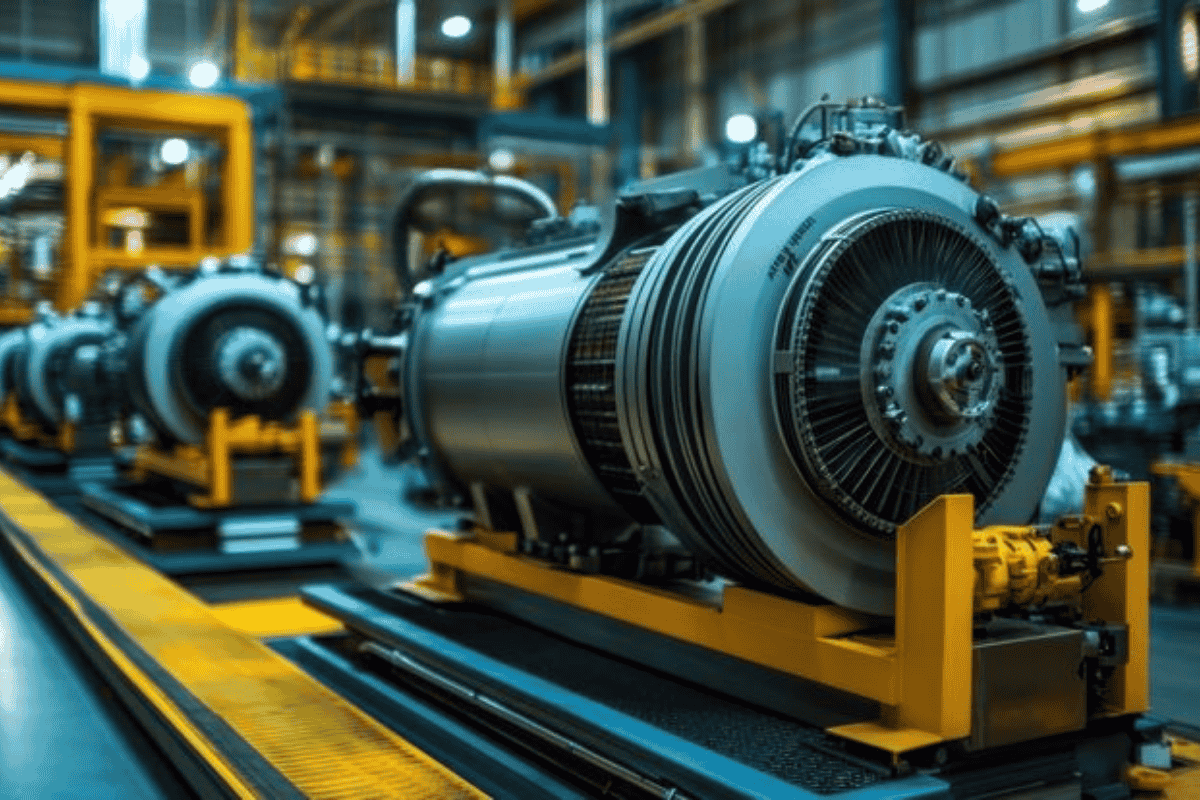

Why Every Factory Should Invest in an Energy Saving Motor

In today’s industrial landscape, efficiency is no longer a luxury—it is a necessity. Rising energy costs, tighter regulations, and growing pressure for sustainable operations are driving factories to rethink their electricity usage. One of the most overlooked yet impactful areas for improvement is motor-driven systems. Motors power virtually every aspect of industrial operations, from conveyors and pumps to fans, compressors, and mixers. Studies show that electric motors account for nearly 70% of a factory’s electricity consumption, meaning even small gains in motor efficiency can lead to substantial savings.

Investing in energy-saving motors is not merely about reducing electricity bills. It is a strategic move that improves productivity, enhances reliability, reduces environmental impact, and strengthens a company’s competitive position. The following sections explore the reasons why every factory should seriously consider upgrading to energy-saving motors.

Energy and Cost Savings

Energy-saving motors, often referred to as high-efficiency or premium-efficiency motors, provide the same mechanical output as standard motors but use significantly less electricity. These motors often exceed efficiency standards set by organizations such as the National Electrical Manufacturers Association (NEMA) in the U.S. and the International Electrotechnical Commission (IEC) internationally.

Key benefits include:

- Reduced electricity bills: High-efficiency motors can reduce energy consumption by 5–20%, depending on size, load, and operating hours. Motors running 24/7 in industrial settings can save thousands of dollars annually.

- Better power factor: These motors optimize electrical power usage, reducing energy waste and cutting utility costs.

- Long-term savings: Replacing multiple motors in a facility can produce cumulative savings, significantly reducing operating costs.

By cutting energy consumption, factories also protect themselves from rising electricity prices, offering both immediate and long-term financial benefits.

Environmental Benefits

Global concern over climate change and environmental degradation has prompted industries to adopt greener practices. Energy-saving motors contribute significantly to reducing a factory’s carbon footprint.

Benefits include:

- Lower emissions: Using less energy helps cut CO2 emissions, which is especially important when electricity is generated from fossil fuels.

- Sustainability credentials: Factories that prioritize energy efficiency demonstrate environmental responsibility, valued by customers, investors, and partners.

- Government incentives: Many countries and energy providers offer rebates or tax incentives for factories adopting energy-efficient technology, reducing installation costs and improving ROI.

Adopting energy-saving motors enables factories to meet sustainability targets, back green initiatives, and strengthen their reputation as environmentally responsible organizations.

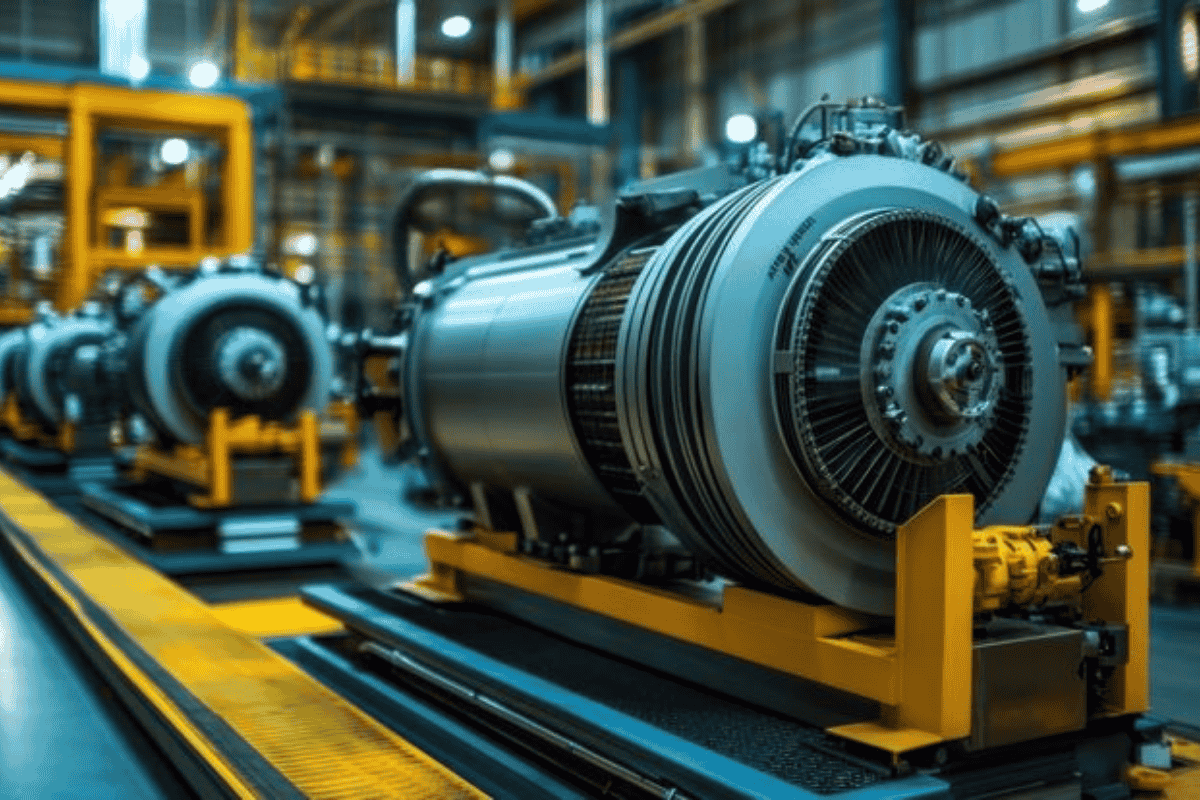

Reduced Maintenance and Longer Lifespan

Energy-saving motors are designed not only for efficiency but also for reliability. They often feature enhanced insulation, superior bearings, and improved cooling mechanisms, which reduce wear and prevent overheating.

Key advantages include:

- Fewer breakdowns: Improved design and materials minimize mechanical and electrical failures.

- Lower maintenance costs: Reduced need for repairs, lubrication, and part replacement lowers expenses and labor requirements.

- Extended lifespan: High-efficiency motors often outlast standard motors by 20–30%, providing long-term reliability and stable operations.

Reliable motors help maintain uninterrupted production schedules, reducing costly unplanned downtime.

Improve Your Equipment Efficiency Now

Unlock better performance and reduce energy waste with expert maintenance and upgrades tailored to your machinery.

Improved Productivity and Performance

High-efficiency motors deliver consistent torque and performance, even under fluctuating loads or demanding industrial conditions.

Benefits include:

- Reliable operations: By maintaining optimal performance, these motors keep production running smoothly and efficiently.

- Enhanced process efficiency: Consistent motor output ensures downstream equipment functions smoothly, improving productivity.

- Versatility: These motors can handle a variety of industrial applications, from chemical processing to material handling.

Stable motor performance reduces operational bottlenecks and improves product quality, enhancing overall efficiency.

Quick Return on Investment

While energy-saving motors often have a higher upfront cost than standard models, their long-term savings quickly offset the initial investment.

Key points include:

- Fast payback: Depending on the cost and electricity usage, the ROI can range from 1 to 3 years.

- Cumulative savings: After the initial investment, the ongoing energy savings become a direct benefit.

- Incentives: Rebates and tax credits for high-efficiency motors further shorten the payback period.

Lower energy bills, reduced maintenance costs, and incentives make energy-saving motors a profitable long-term investment.

Regulatory Compliance

Energy efficiency standards for industrial motors are becoming increasingly strict worldwide. Governments and regulatory bodies enforce these standards to reduce energy consumption and environmental impact.

Benefits include:

- Avoid fines and penalties: Compliance with U.S. DOE regulations or Europe’s IE3/IE4 efficiency classifications ensures factories meet legal requirements.

- Future-proof operations: Early adoption positions factories to meet stricter future regulations without costly retrofits.

- Operational planning: Compliance reduces the risk of sudden, unplanned upgrades or shutdowns.

Investing in energy-saving motors today safeguards factories against evolving legal and environmental pressures.

Corporate Image and Market Competitiveness

Sustainability has become a strategic asset in modern business. Investing in energy efficiency demonstrates a company’s commitment to responsible, forward-looking operations.

Key advantages include:

- Enhanced brand reputation: Factories demonstrate environmental responsibility, gaining credibility with customers, investors, and stakeholders.

- Access to eco-conscious markets: Sustainable operations attract clients and partners who value green practices.

- Competitive differentiation: Efficiency in energy use strengthens a company’s position in sectors where sustainability and cost considerations influence decisions.

Adopting high-efficiency motors not only improves efficiency but also reinforces a company’s image as a responsible organization.

Smart Technology Integration

Modern high-efficiency motors are often compatible with digital monitoring and automation systems, enabling smart factory operations.

Benefits include:

- Real-time monitoring: Track performance and energy usage instantly for informed decisions.

- Predictive maintenance: Detect anomalies early to prevent costly failures.

- Data-driven optimization: Integrated motors help improve efficiency, reduce waste, and optimize resources.

Smart integration ensures that energy-saving motors not only reduce costs but also enhance operational intelligence.

Conclusion

Energy-saving motors are one of the most effective investments a factory can make to reduce costs, improve performance, and support sustainability. They deliver measurable energy and cost savings, reduce maintenance needs, extend motor lifespan, and ensure regulatory compliance. Additionally, they strengthen corporate reputation, enable smarter factory operations, and provide a significant competitive advantage.

Although high-efficiency motors have a higher initial cost, the long-term benefits far outweigh the expense. Factories that adopt these motors position themselves as efficient, responsible, and forward-thinking, ready to meet the challenges of modern industrial operations. In today’s environment, where energy efficiency, cost reduction, and environmental responsibility are interconnected, investing in energy-saving motors is not just a smart choice—it is a strategic imperative.

PPM

Predict. Prevent. Maintain. For Reliability, Efficiency, and Sustainability

Recent Posts

- All Post

- Equipment Monitoring

- Maintenance Strategies

- Predictive Maintenance

- Preventive Maintenance

- Professional Services

Get In Touch!

Reach out to us for expert assistance in implementing predictive and preventive maintenance solutions tailored to your needs.